Key Benefits of Comprehensive Inspection

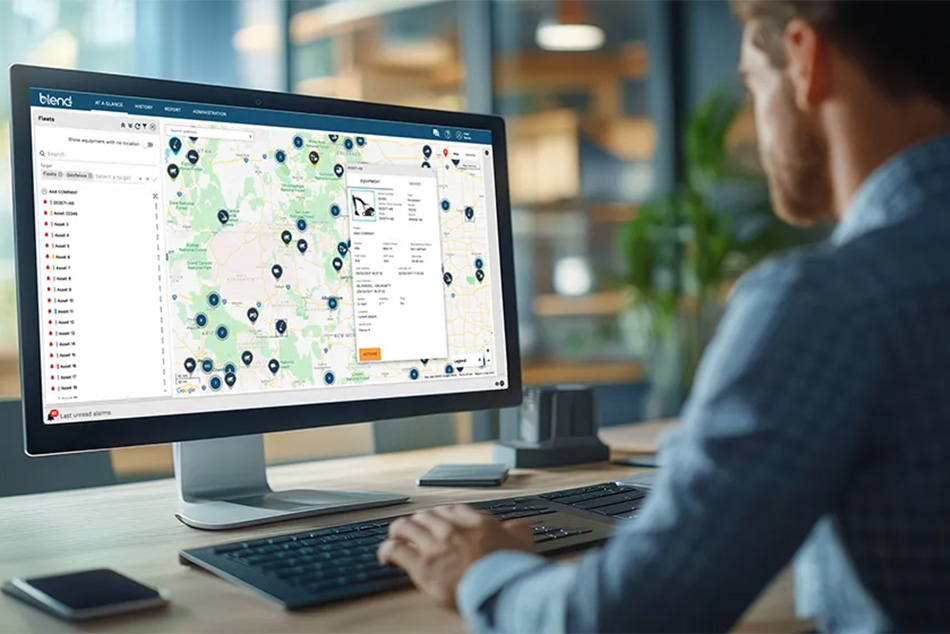

A broad rail inspection strategy offers tangible advantages through precise and immediate data management, ensuring the fastest possible acquisition of track geometry measurements. This is crucial for optimizing tamping operations and assessing slab tracks. The advanced approach provides real-time identification and classification of track defects across all sections, enabling rapid responses to emerging issues.

Furthermore, the system excels in visualizing, analyzing, and reporting track defects. Clear visual data empowers engineers, streamlining decision-making, resource allocation, and post-tamping quality checks. By intelligently merging and monitoring multiple measurements, comprehensive inspection offers unmatched track data evaluation, supporting predictive maintenance and optimizing resource utilization for all track types, including slab tracks. This integrated approach consistently upholds the highest safety standards across the network.

Tamping

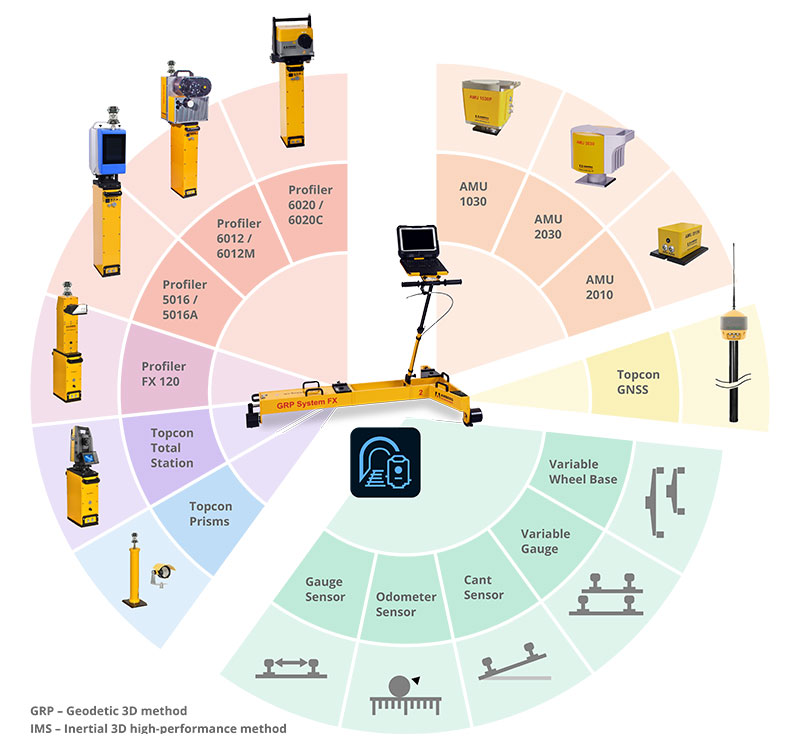

Identify track position errors for ballast track construction and maintenance, enable comprehensive design data definition (absolute/relative alignment) with import/export interfaces, prepare interactive correction data for tamping machines (e.g., Plasser&Theurer, Matisa, Harsco), provide detailed reporting on track alignment and control points, and offer integrated control point surveying as a stand-alone feature.

Slab Tracks

High-precision systems support all slab track construction stages with real-time correction value displays, interactive sleeper-based data preparation, acceptance mode for final track position documentation, and detailed numerical and graphical reporting for contractors. The Slab track configuration works with the Topcon Econo Tilting Prism Assembly (Item ID: 724806).

Related products

Get in touch

Thank you! We will be in touch.