“Once we got out of the ground and started pouring elevated decks, progress has been steady,” he said. “When we got to the 8th level, where the typical floors start, we were able to utilize a tableized form system which allows us to streamline the deck pour process. We do our first deck pour on Monday and pour vertical that afternoon. Tuesday morning we will stress the cables and once that’s done and everything is within spec, we fly our tables, put rebar down and are ready to start again. We do pour two on Wednesday and it’s the same scenario: pour it, stress the deck the next day, fly the tables and so on. It’s a pretty quick turn.”

That last statement might be a bit of an understatement. According to Black, while The Allen project was bid as a six-day turn — one floor completed every six days — they are bettering that by a nice margin.

“We are currently doing a floor every five days,” said Black. “The end result is that we will probably finish one month ahead of schedule and pick up any bonuses that were in the bid package. While that’s great for us, finishing early also makes for a satisfied customer and owner; in the end everybody wins.”

Busy Schedule

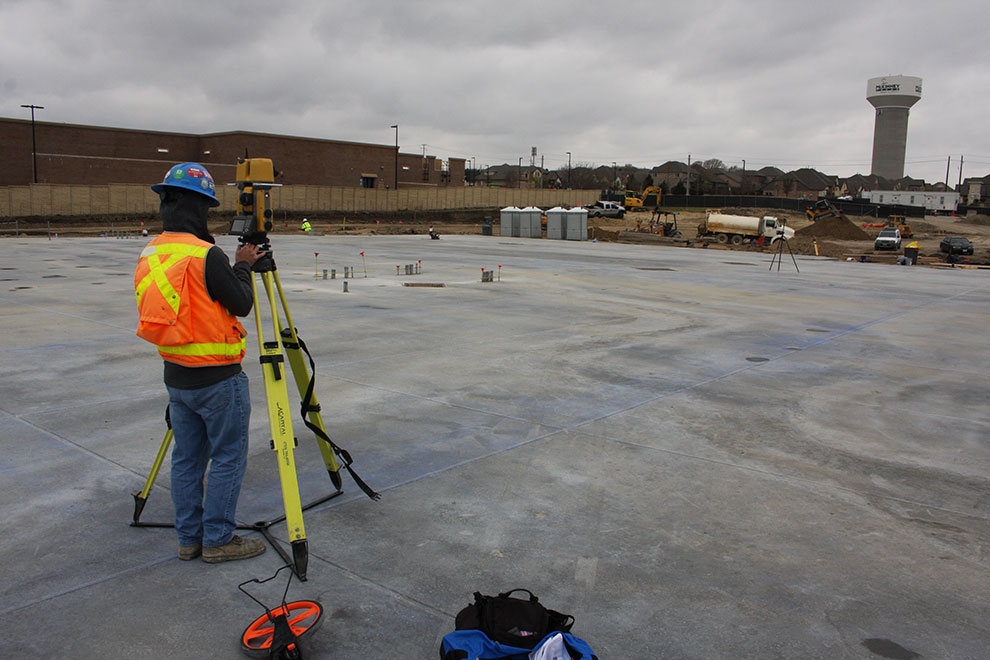

With the concrete set, TAS brings in Walter Zuniga, one of its field engineers, to set up the GTL, make the scans, and collect the data — all without holding up any of the other trades. The process is so quick and unobtrusive that Zuniga can do his scans at The Allen twice a week and on the other three days be at any of TAS’s other jobs.

“That’s really key,” said Black. “It’s not just structural decks we’ve poured that need scanning. Other work can include light commercial, industrial super flat floors, and more — it’s all important. In fact, on warehouse floors, it is even more critical because of the impending heavy forklift traffic and shelves that will be stacked to the ceiling. So, Walter can cover a lot of ground in a short period of time, ensuring solid verification on each one.”

Zuniga said that, despite the wealth of data it produces and the value it holds, operating the new system was easy to grasp, even for someone not well-versed in scanning and surveying technology.

“The GTL was my first experience with technology of this type, but I found it very simple to use and understand,” he said. “It looks like a lot to take in at first, but at the end of the day, it is the same data we would get with any topo — just a whole lot more of it. The GTL allows me to scan and then, within minutes, move on from that position, allowing other workers to come behind me. Then, working from my vehicle and still onsite, I can generate an FF/FL report and have it to the GC in minutes.”

Powerful Tool

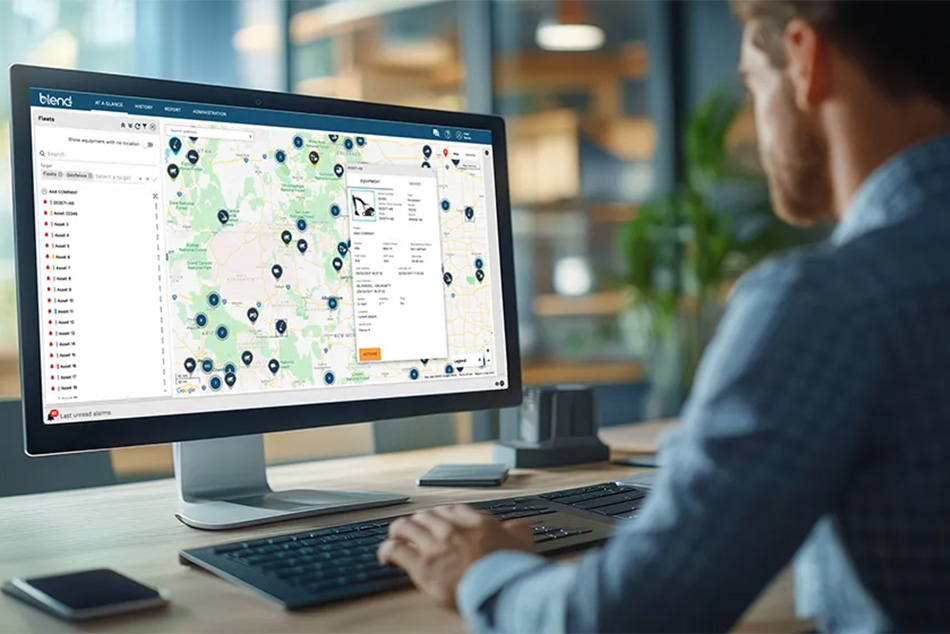

Valenzuela added that, despite the speed at which scans can be taken, there is not necessarily a huge time savings using the newer approach to verification — the general contractor still gets his data in 24-48 hours as in the past. What is different, however, is the amount of info being handed over (and available for later retrieval), the elimination of missed data points, the better allocation of manpower, etc.

“It’s really all about having the amount of data available to verify any and all of our work,” he said. “Although, in the past, we wouldn’t even send that data until it was needed. Now, we find it’s better to present the GC with it right out of the gate — they love it. They appreciate the info and know the value it holds. That’s a powerful tool for us.”