Remote site management

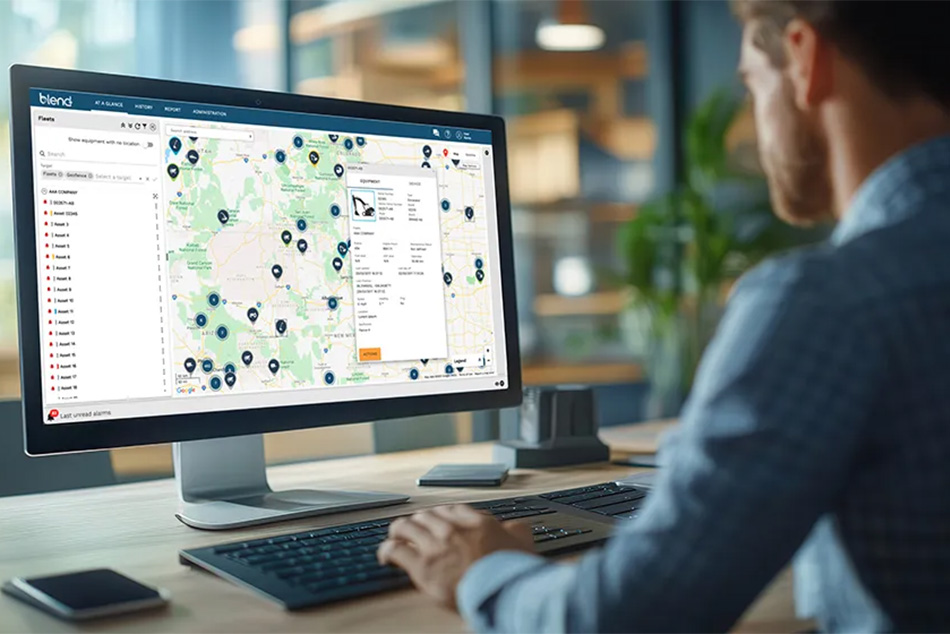

The O’Brien Contractors Ltd team used Topcon’s Sitelink3D v2 software to effectively collaborate and manage the project. The company is the first in the UK to move to the innovative web-based platform, that provides remote access and support to every machine connected to the system – including file transfers, messaging, reporting and analytics. This means any potential machine downtime is dramatically reduced as issues can be resolved in real time without the need for on-site technical support. Instead, engineers can troubleshoot operator queries remotely and ensure work continues with minimal delay.

O’Brien Contractors Ltd reaped the benefits of Sitelink3D v2, rendering a 3D model in the tendering stages of the project to help demonstrate the works that were to be carried out. The software’s data management ecosystem allowed teams to quickly make alterations to the model to coincide with real-time information throughout the application process, and ultimately gave the team an edge against competitors.

Once works had started, an unexpected challenge arose when the team found a difference in ground material that was not detected in the early stages of development – the layer of topsoil at the new site was significantly deeper than it had appeared on initial site surveys. O’Brien Contractors Ltd was able to add the new data into Sitelink3D v2 and plan budgets, timings and resources, automatically synching the new data to the relevant machines working on site with no delay to the plant operations, avoiding an expensive break in the project.

Minimising the impact

Fundamental to the success of the project was the ability for O’Brien Contractors Ltd to carry out the works with minimal disruption and impact to the local environment, given the site’s close proximity to a busy residential area. Using Topcon’s MC-X and Sitelink3D v2 machine control workflow, the team has been able to synchronise data between the site and office without the need for engineers to travel between the two, with the reduced traffic to site meaning less disruption for local residents.

With the reduced machine hours needed to complete the job when using Topcon machine control, fuel use is greatly reduced meaning lower costs and lower carbon footprint. Furthermore, the increased accuracy of the technologies reduces the risk of costly mistakes and the requirement for reworks.

Tom continued: “This project was a huge undertaking, with the equivalent of 17.3 acres worth of land being relocated from one site to the other. We’ve worked with Topcon for some years now and we’ve always received expert support to maximise the potential of our equipment, and it was no different on this project. Topcon’s team worked closely with us to integrate MC-X and Sitelink3D v2 – the transition was seamless and we’ve been able to deliver this project on time, on budget and with minimal disruption.”

Andy Flood, Business Manager at Topcon Positioning GB, said: “It’s been brilliant to see the O’Brien Contractors Ltd team use our MC-X machine control hardware and Sitelink3D v2 software to their full potential. We've been able to see first-hand how innovations within our sector are crucial in helping teams carry out challenging works, improving health and safety and, ultimately, allowing contractors to deliver work on time and on budget.”