Data is Key

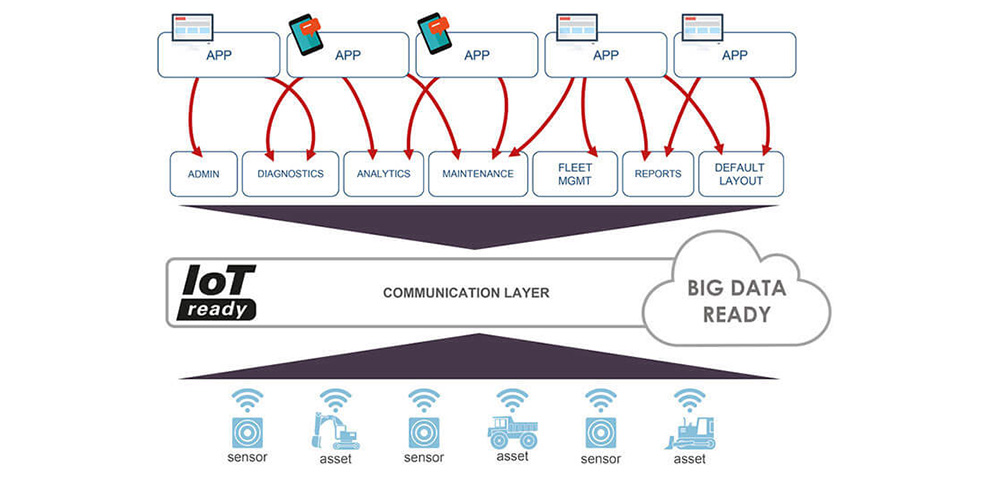

Smart, connected construction equipment can allow tracking of how they are being used. Through the accumulation of historical data, the IoT platform can build patterns of information to better understand customer-contractors’ necessities, the environment in which they operate, and provide advanced solutions to fit their needs. Indeed, data collected from smart, connected products and systems provide detailed information on how the products’ features are used, which are most useful, and which are ignored.

The collected data, which is called Big Data, provides options for different types of analysis:

- Descriptive — to retrieve a detailed report of current conditions and understand what happened in a specific working environment;

- Predictive — to provide a reliable prediction about product performances and forestall the occurrence of potential malfunctioning or damage;

- Prescriptive — to know how to optimize and automate the process and the workflow via real time project maps and plans which feed the machines.

The platform provides numerous and detailed information that can be selected according to the need at the time. This enables making effective and profitable choices. It is possible to retrieve virtually any useful information, from fuel consumption to equipment productivity, from maintenance services to, in the near future, prognostics. In addition, most of the functionalities are completely customizable, for meeting specific contractor needs (e.g. dashboard layout, alarms and notifications, CAN-Bus parameters, units of measurement, language).

For the contractor owners and managers, analytics is possible to compare usage patterns in order to improve services, increase productivity, ensure better quality, and create more accurate pricing and bidding strategies.

The ultimate benefits of Big Data are cost reductions and deeper insights as to what customers need.

“Interconnected smart technology is both central to how we engineer our solutions and produce their functionality for our customers,” said Di Federico. “The challenges, as with most innovation, have mostly to do with adoption. Once construction contractors have an opportunity to see first-hand how the solutions we provide make them more efficient, the concept of IoT makes perfect sense. Greater productivity means undeniable higher profits for their businesses, and assists them in meeting what we at Topcon call The Intersection of Infrastructure and Technology. It is the meeting point where construction productivity is improved by applying intelligent positioning technology, and clearly IoT is part of this bigger picture.”

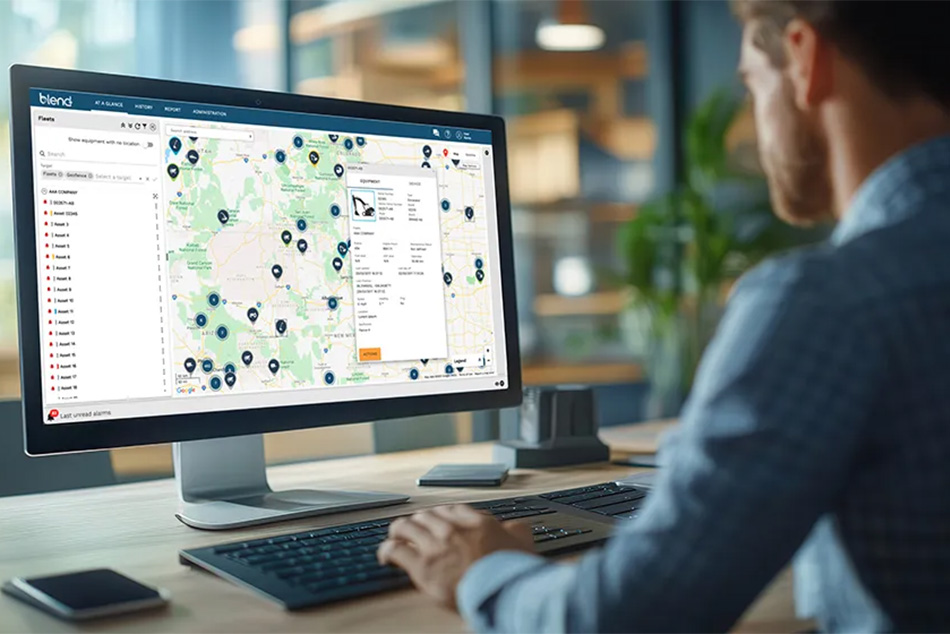

For Topcon and other technology companies in its niche, providing connected solutions to the construction market enables contractors to have comprehensive monitoring of conditions, operations and the work site through sensors and data. This means monitoring knows no boundaries. Assets can be monitored from everywhere, wherever the contractor happens to physically be. It enables real-time communication and task management with machines and crews on the work site. Additionally, the entire fleet of machines working at the site can be connected.

“We call it ‘descriptive, predictive and prescriptive’ analytics,” Di Federico said. “The result for customers is higher productivity, less downtime and waste, and ultimately more profitability, combined with less stress.

“We absolutely design our solutions with IoT top of mind, such as our Topcon Tierra remote asset management system that provides total visibility and control, including diagnostics and maintenance for reducing costs and improving performance.

"Our MAGNET software solutions suite, provides real-time connected support for hardware as well as integration with our Sitelink3D service for instant data transfer and connectivity into active project sites. Additionally, Sitelink3D allows customers to plan, schedule, assign tasks and get reports, all in real time. When practically any new product or system is designed, integration with these solutions is standard and expected procedure.”

The IoT is here to stay. It is the future, and for many it is the present. In the construction market, the success of technology that enables construction contractors to bid projects more accurately based on their own historic production data and get their jobs completed faster, more accurately, and more efficiently using intelligent interconnected technology, has raised customer expectations.

"For construction contractors and OEMs today the tremendous benefits of IoT enhances the decision-making process for obtaining the best possible management of resources, fleets and personnel," said Di Federico.